Well after 800 hours of TW time I finally bolloxed it up

Never been an AD on an MT prop

There was no AD on mine but there was a 'mandatory' change to the hub to incorporate different seals. Apparently the new seals don't throw grease as badly as the traditonal MT seals, and my experience has confirmed that - very little grease thrown compared to the original seals.

There was no AD on mine but there was a 'mandatory' change to the hub to incorporate different seals. Apparently the new seals don't throw grease as badly as the traditonal MT seals, and my experience has confirmed that - very little grease thrown compared to the original seals.I'm not a great fan of my MT prop. It works OK but it's just a wood prop with a bit of fiberglass on top. That glass is very thin so it doesn't fly off under centrifugal loads, and it tends to crack near the hub letting water get to the wood. The blades are held into the hub with lag screws into the end grain, which is a very old fashioned technique. Mine has the crudely formed stainless steel leading edge protection and I remove corrosion with Scotchbrite after every flight. It's true that the the blades can be reworked many times, but they tend to need that attention in my experience. It's a bit of a delicate device.

Certainly some compelling reasons to look closely at the MT option.

The only words of caution I would give are;

It sounds very like to me the mandatory hub replacement Silvaire mentions is an AD by another name.

You say no TBO, but in reality what life are owners getting from the blades?

I know there will be regional variations but I've heard murmurings about lack of suitably factory qualified people to to work on the MT props. This may be just my part of the world.

The only words of caution I would give are;

- Ensure you're comparing apple with apples.

- How many of the enthusiastic reviews are very recent owners without the benefit of a few years operations.

- Very often it's not what's said in the marketing info but rather what's left unsaid that really matters.

It sounds very like to me the mandatory hub replacement Silvaire mentions is an AD by another name.

You say no TBO, but in reality what life are owners getting from the blades?

I know there will be regional variations but I've heard murmurings about lack of suitably factory qualified people to to work on the MT props. This may be just my part of the world.

Buy the cheapest option. The Maule is already a pretty good performer. Why pay more to get a few percentage increase in performance that you are highly unlikely ever to use ?

Thread Starter

Join Date: Aug 2005

Location: Glens o' Angus by way of LA

Age: 60

Posts: 1,975

Likes: 0

Received 0 Likes

on

0 Posts

Went down to the engine shop that's doing the tear down and inspection. The engine was just being put on a stand after being removed from the plane just as I arrived. The boss of the engine shop suggested that if I had a spare hour or so I could watch them take it apart. I couldn't believe they had it completley disassembled in about 90 minutes.

I asked him what are the top reasons engines come to him prior to reaching TBO. He gave 2 reasons:

1. Lack of use, and lack of use where the owner thinks starting and running it on the ground is doing good when in fact the opposite is true, it accelerates water corrosion damage to the engine.

2. Cooking the engine, an example he gave is not returning the engine to idle after run up and instead leaving it running at 14 or 1500rpm while you faff around copying your IFR clearance then taxi up to the hold short as number 3 and have to wait, all the while at higher rpm than idle and on a hot day.

He showed me a Lycoming 360 that came in for overhaul that had 4000 hours put on it in the last 5 years. The engine was in excellent condition and within factory tolerances, he also pointed out another engine that he had just taken out of service it had a stamp on the side that said "46" which to my amazement he pointed out meant it was made in 1946 !!

He also said he's had quite a few owners bring their planes to him with low compression on one cylinder and enquire about prices to replace the cylinder or even a complete overhaul before TBO , he suggested that prior to taking it apart they put a cap of some type of engine cleaning product, I can't remember the brand, in each cylinder, a quart in with the oil and a 2% mixture in with the fuel and take it for a 5 hour flight and this normally cleans out the cylinders and rings and returns the cylinder to an acceptable compression. Pretty cheap solution to what appeared to be a major problem.

Quite interesting stuff,

I asked him what are the top reasons engines come to him prior to reaching TBO. He gave 2 reasons:

1. Lack of use, and lack of use where the owner thinks starting and running it on the ground is doing good when in fact the opposite is true, it accelerates water corrosion damage to the engine.

2. Cooking the engine, an example he gave is not returning the engine to idle after run up and instead leaving it running at 14 or 1500rpm while you faff around copying your IFR clearance then taxi up to the hold short as number 3 and have to wait, all the while at higher rpm than idle and on a hot day.

He showed me a Lycoming 360 that came in for overhaul that had 4000 hours put on it in the last 5 years. The engine was in excellent condition and within factory tolerances, he also pointed out another engine that he had just taken out of service it had a stamp on the side that said "46" which to my amazement he pointed out meant it was made in 1946 !!

He also said he's had quite a few owners bring their planes to him with low compression on one cylinder and enquire about prices to replace the cylinder or even a complete overhaul before TBO , he suggested that prior to taking it apart they put a cap of some type of engine cleaning product, I can't remember the brand, in each cylinder, a quart in with the oil and a 2% mixture in with the fuel and take it for a 5 hour flight and this normally cleans out the cylinders and rings and returns the cylinder to an acceptable compression. Pretty cheap solution to what appeared to be a major problem.

Quite interesting stuff,

Join Date: Oct 2014

Location: Radlett

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

piperboy84:

I was always taught to keep the engine at 1200rpm. Are you saying even that is too high?

2. Cooking the engine, an example he gave is not returning the engine to idle after run up and instead leaving it running at 14 or 1500rpm while you faff around copying your IFR clearance then taxi up to the hold short as number 3 and have to wait, all the while at higher rpm than idle and on a hot day.

Thread Starter

Join Date: Aug 2005

Location: Glens o' Angus by way of LA

Age: 60

Posts: 1,975

Likes: 0

Received 0 Likes

on

0 Posts

Thread Starter

Join Date: Aug 2005

Location: Glens o' Angus by way of LA

Age: 60

Posts: 1,975

Likes: 0

Received 0 Likes

on

0 Posts

My shiny new MTV-9-B/200-52 78.8" three blade composite prop, Kevlar spinner, nickel leading edges is on the truck from Wisconsin to California to be put on the inspected and port polished engine.

Insurance is paying for about 90% of the prop. And the AI reckons he'll have the field approval paperwork done in 2 weeks.

Insurance is paying for about 90% of the prop. And the AI reckons he'll have the field approval paperwork done in 2 weeks.

Thread Starter

Join Date: Aug 2005

Location: Glens o' Angus by way of LA

Age: 60

Posts: 1,975

Likes: 0

Received 0 Likes

on

0 Posts

Getting to the end of my tether with the engine issue on the Los Angeles based Maule. Here is a recap. 2007 aircraft ( Lycoming 360 )with 275 hours since new. Had a prop strike earlier this year where the prop hit the dirt while taxiing at idle. Insurance covered a complete tear down and inspection which showed the engine was fine, during the rebuild I changed the 2 blade Hartzell out for a 3 blade MT. Picked the plane up from the shop, upon getting it back to the home field I taxi for about 2 minutes then do a mag check. The number one cylinder on the right mag (bottom plug) temperature on the EGT gauge drops off the bottom of the scale, I lose 3 to 4 hundred rpm and the engine farts and pops. While 2,3 & 4 rise as normal, I power up to 2300 rpm and aggressively lean then return back to 2000rpm for a mag check and it clears.

After each and every short taxi whether before or after a flight the #1 cylinder/plug fouls up and takes aggressive leaning to clear ( I always lean for taxi) . I take it to an on-field repair shop who remove, rotate, test and gap the plugs but the problem stays with the cylinder and mag (#1 on the bottom). I taxi out and itís the same **** all over again, while flying at cruise rpm I notice the #1 cylinder is consistently hotter than the others by about 120 degrees while this is not excessive it is consistently the #1 that runs hotter, I would have thought it being on the front it would have perhaps been the same or even cooler than 3 or 4 on the back. A mag check while cruising shows everything is running within tolerance and smoothly. Over the next 25 hours I use twice the normal oil consumption compared to pre prop strike.

I go back to the engine shop and they say it just needs a bit more running in, I request a compression check and get 70,70,74,76 which again is within tolerance but prior to the teardown I was getting between 74 to 76 across the board. I chalk the 70ís up to the rings settling in and hope for better numbers. They bore scope the #1 and can see the cross hatch from the honing clearly and no glazing. They suggest we adjust the mixture and test and adjust the mags, upon flying and landing I get the same old ****. I return it to the shop and tell them that after 25 hours of flight the cylinder and rings should have settled in so they agree to remove it and do a light re-hone and new rings on number 1. They advised I takeoff and hold at full power for an hour flight, after landing at the home field and taxiing I get the exact same problem again.

Iím tired of going back to the engine shop and having the local field mechanic change or rotate the fouled plug and have to decide what to do next. My choices:

1. Live with it and spend 2 or 3 minutes aggressively leaning each run-up with the plane farting and popping and shaking and excessive oil consumption.

2. Write to the insurer and tell them after 3 months, 30 hours of flight time and 4 visits back to mechanics and a cylinder re-honing of #1 ( in addition to the re-honing of all 4 at the initial teardown) I want a complete new engine as this could be a dangerous situation and is unacceptable.

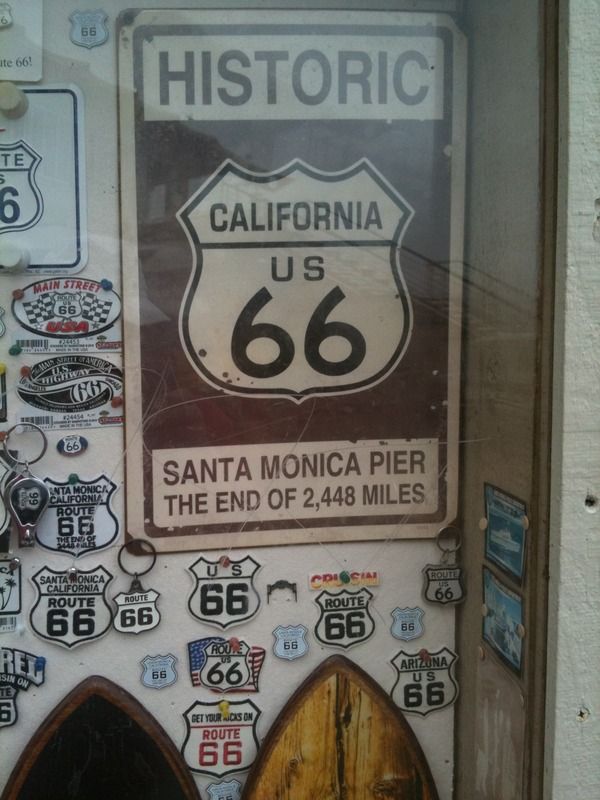

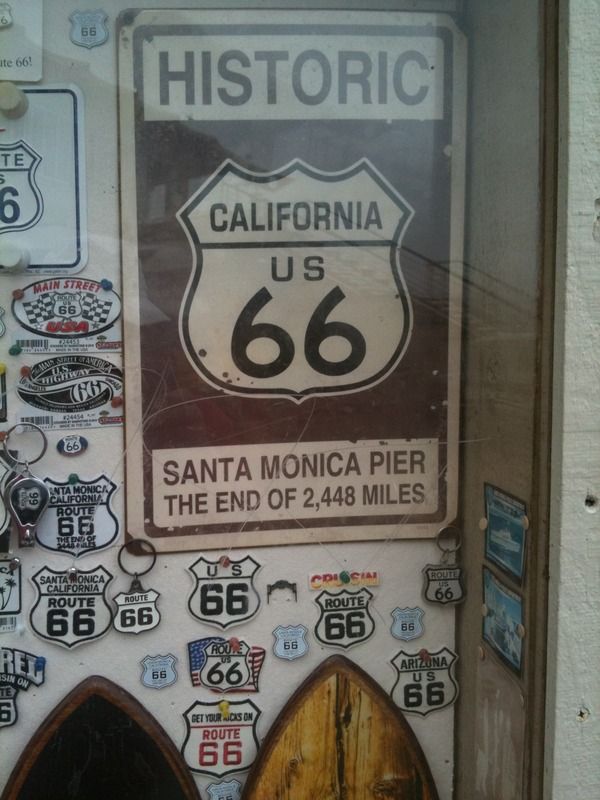

3. Jump of Santa Monica Pier or take up lawn bowling as a hobby.

Any thoughts?

After each and every short taxi whether before or after a flight the #1 cylinder/plug fouls up and takes aggressive leaning to clear ( I always lean for taxi) . I take it to an on-field repair shop who remove, rotate, test and gap the plugs but the problem stays with the cylinder and mag (#1 on the bottom). I taxi out and itís the same **** all over again, while flying at cruise rpm I notice the #1 cylinder is consistently hotter than the others by about 120 degrees while this is not excessive it is consistently the #1 that runs hotter, I would have thought it being on the front it would have perhaps been the same or even cooler than 3 or 4 on the back. A mag check while cruising shows everything is running within tolerance and smoothly. Over the next 25 hours I use twice the normal oil consumption compared to pre prop strike.

I go back to the engine shop and they say it just needs a bit more running in, I request a compression check and get 70,70,74,76 which again is within tolerance but prior to the teardown I was getting between 74 to 76 across the board. I chalk the 70ís up to the rings settling in and hope for better numbers. They bore scope the #1 and can see the cross hatch from the honing clearly and no glazing. They suggest we adjust the mixture and test and adjust the mags, upon flying and landing I get the same old ****. I return it to the shop and tell them that after 25 hours of flight the cylinder and rings should have settled in so they agree to remove it and do a light re-hone and new rings on number 1. They advised I takeoff and hold at full power for an hour flight, after landing at the home field and taxiing I get the exact same problem again.

Iím tired of going back to the engine shop and having the local field mechanic change or rotate the fouled plug and have to decide what to do next. My choices:

1. Live with it and spend 2 or 3 minutes aggressively leaning each run-up with the plane farting and popping and shaking and excessive oil consumption.

2. Write to the insurer and tell them after 3 months, 30 hours of flight time and 4 visits back to mechanics and a cylinder re-honing of #1 ( in addition to the re-honing of all 4 at the initial teardown) I want a complete new engine as this could be a dangerous situation and is unacceptable.

3. Jump of Santa Monica Pier or take up lawn bowling as a hobby.

Any thoughts?

Join Date: Sep 2015

Location: London

Posts: 442

Likes: 0

Received 0 Likes

on

0 Posts

Personally I'd take it to the shop and tell them that I'm not leaving until this issue is FULLY fixed. Tell them that the next time they say the plane is fixed, you'll force the head mechanic to come with you on the flight and if **** hits the fan its not just your life in the balance!

This issue sounds to me like something is just waiting to go seriously wrong.

But then again - the prospect of lawn bowling is somewhat appealing after the stresses involved in getting this fixed!

This issue sounds to me like something is just waiting to go seriously wrong.

But then again - the prospect of lawn bowling is somewhat appealing after the stresses involved in getting this fixed!

I don't see any reference to checking the timing on the right mag. I mention this, not as any kind of expert, but because a friend of mine had a similar problem on his Cardinal. In his case it was both mags and the engine would only run smoothly with the mixture leaned. His original engineers could not find anything wrong so he went to a second shop where they found that the timing was out on both mags.

pb84,

Sorry to hear you are still having problems with your "little yellow airplane". When the engine was rebuilt, were any parts replaced?

I've forwarded your "cri de coeur" to the tow pilots in my gliding club, who collectively have thousands of hours behind O-360s. I'll let you know if I get any useful replies.

Concerning your third choice, I can't see you fitting in at a lawn bowling club. I think the pier option is better, but given its historic location, you should do it James Dean style, in a Porsche!

Sorry to hear you are still having problems with your "little yellow airplane". When the engine was rebuilt, were any parts replaced?

I've forwarded your "cri de coeur" to the tow pilots in my gliding club, who collectively have thousands of hours behind O-360s. I'll let you know if I get any useful replies.

Concerning your third choice, I can't see you fitting in at a lawn bowling club. I think the pier option is better, but given its historic location, you should do it James Dean style, in a Porsche!